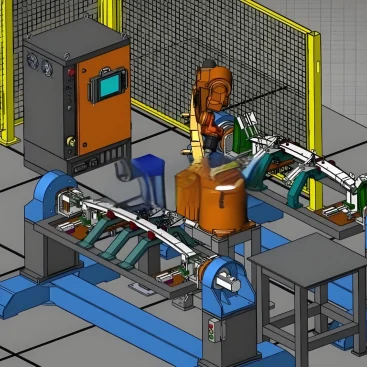

Wid Automation's welding robot workstations combine precision, AI technology, and versatility to automate tasks, boost efficiency, and enhance safety across various industries.

Our Agricultural machinery welding production line for agricultural machinery delivers unmatched durability and precision, engineered to withstand the rigorous demands of farming equipment. From plows and tillers to harvesters and tractor components, our systems utilize heavy-duty robotic MIG welding, submerged arc welding (SAW), and adaptive CNC controls to handle thick steel plates, complex geometries, and high-stress joints.

Our Aluminum alloy shelf welding production line combines cutting-edge automation with specialized engineering to deliver high-strength, lightweight, and corrosion-resistant storage solutions. Designed for industrial, commercial, and logistics applications, our systems employ robotic MIG/TIG welding and laser alignment technologies to ensure seamless joints and structural durability.

Certified welding processes validate beam integrity through 50+ mph simulated collision tests. Our lines incorporate inline hardness testing (Rockwell C-scale) and AI-powered defect detection (99.98% accuracy) to guarantee weld consistency across ±0.2mm positional tolerance. Full MES integration ensures traceability from raw material to final assembly.

Our Automobile chassis welding production line integrates cutting-edge robotic systems with AI-powered quality control, delivering precision welding for unibody and frame structures. Featuring 6-axis industrial robots with laser-guided positioning, the system achieves ±0.1mm repeat accuracy, ensuring consistent weld seam quality across SUVs, EVs, and commercial vehicles.

Our automotive body welding production line leverages advanced robotics and AI-driven control systems to deliver micron-level accuracy for high-strength vehicle body construction. Engineered for multi-material architectures—including ultra-high-strength steel (UHSS), aluminum alloys, and carbon-fiber composites—this fully automated line ensures flawless welds for crash-critical components like pillars, rocker panels, and roof structures.

An automotive roof welding fixture is a specialized tool used in vehicle manufacturing to securely position and align a car’s roof panel during the welding process. Designed for precision, these fixtures ensure that the roof component is held in the correct orientation relative to other body parts, such as pillars, side panels, and crossmembers.

Our swing arm welding production line is engineered for precision fabrication of construction machinery booms, cranes, and excavator arms. Utilizing robotic MIG/MAG welding systems with adaptive arc sensing, it handles steel plates from 10mm to 50mm thickness while maintaining weld integrity under extreme loads.

Our Car dashboard fixture employ aerospace-grade aluminum alloys and servo-controlled clamping mechanisms to secure components with ±0.02mm repeatability. Designed for multi-model compatibility (SUV/sedan/electric vehicles), the modular system reduces changeover time by 60% through patented quick-release pins and RFID-tagged tooling.

Jiangsu Wid automation Co.,Ltd

Complete Assembly | Integrated Workstation | Plug-and-Play | No On-Site Installation Required

© 2025 Jiangsu Wid Automation All Rights Reserved.

Designed by AdmarV